ModTrax™

High Performance

Sliding Door Systems

ModTrax™

High Performance Sliding Door Systems

ModTrax is the premier commercial interior sliding door system manufacturer in the US. We’ve collaborated with architects, designers, and installers to engineer and design a sliding door system that offers:

- Pre-assembled track system set to the clear opening

- Removable soft closers without removing or readjusting the door

- Acoustic & smoke gaskets options

- Space saving low maintenance design that recovers 9 to 30 sq. ft.

- Installs in 6 easy steps… without a certified installer

- Fits any door manufacture with endless hardware options

Other sliding door systems require time consuming on-site track assembly. Which leads to outrageous labor costs and delayed completion. At ModTrax, your track is pre-assembled and set to the clear opening which reduces installation time and labor cost.

“Manufacturing is more than just putting parts together. It’s coming up with ideas, testing principles, perfecting the engineering and final assembly.”

– James Dyson

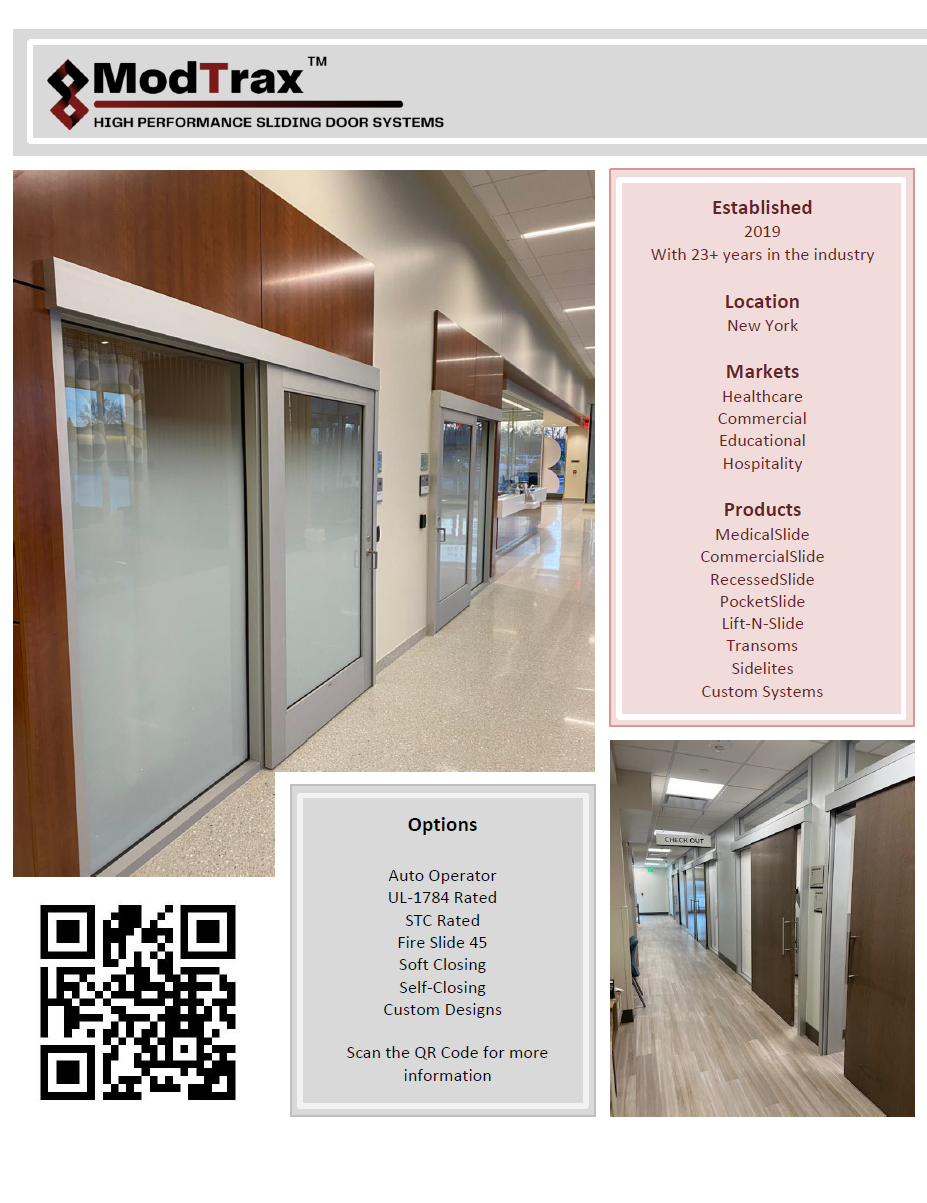

Medical

Slide™

Tailored to the demanding needs of the healthcare industry, the MedicalSlide™ is quickly becoming the “go to” system.

Commercial

Slide™

A practical and efficient way to save space without compromising design in a demanding real-estate market.

Recessed

Slide™

The most space saving and unique design of its class is quickly becoming a “staple” and design favorite.

Bi-

Parting

The bi-parting system offers space saving features like no other, designed for large openings with an array of options.

Pocket

Slide™

A must have in construction. Many call the PocketSlide™ a lifesaver. Used in areas where swing doors are not an option.

Request An Estimate

Contact us today to request an estimate or CAD/Revit/Specifications. Speak to one of our experienced professionals to schedule a presentation.

The Benefits

Effortless Assembly

No Certified Installer Needed…

All tracks come pre-assembled and set to the clear opening. This reduces the cost of Installation, saves time and eliminates mistakes in assembly

SMOKE & ACOUSTICS

Available Options…

Smoke and acoustic options available: enhanced gaskets, mechanical self-closers, auto door gaskets at the head & bottom of the door, trailing edge gaskets and more…

APPEARANCE & DESIGN

Innovative Space Savings Design…

Stunning interior design that makes a bold statement. Innovative & space saving when compared to conventional hinge door

STC RATED 39

Acoustics / ASTM E90

For enhanced Acoustics use our Custom Auto Door Gaskets at the Bottom and Head of the Door. Now for the first time ever you can choose from a variety of doors with ratings anywhere from 32-39, based on the client’s needs and budget.

SOFT CLOSE & SAFETY FEATURES

Safe and Secure

Soft close features when you open and close the door to ensure safety. Our Active Safety Feature prevents the doors from coming off the track.

ModTrax Care Plan

Includes all OEM Parts & Shipping

Avoid costly service calls, prevent downtime, keep doors working efficiently. Eradicate unsafe conditions and extend the life of your sliding door system.

DOORS & HARDWARE SAVINGS

Endless Options

We let you supply the Door & Hardware, this saves on the cost, reduces the lead time and doors match the hinge doors identically. ModTrax offers an array of ADA compliant hardware in various series, functions, and finishes.

ModTrax Custom Design

Custom Design Systems

Each project presents its own challenge and we look forward to working with you on your next custom designed project. We collaborated with architects and designers to create the best customizable system available on the market today.

Door Gaskets & Features

Patented Door Gaskets

Unique to ModTrax is our auto door gaskets at the bottom of the door and head of the jamb. Our gaskets are custom designed and pre-installed in the door pocket and surrounding jamb.

(833) BRN-DOOR

(833) BRN-DOOR